Improve Customer Satisfaction Scores

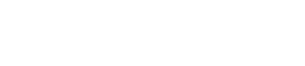

After a product update, my client saw a drop in their customer satisfaction scores. Data showed that delivery specialists were delivering the original product instead of a newer version. A collaborative action mapping session uncovered the root cause: team members were not following the newly-created standard operating procedure (SOP). We set out to bridge the knowledge and skill gap through training, and partner with stakeholders to roll-out accompanying environmental interventions.

Client

Fitness Equipment Manufacturer

Designers

Tom Moyse

Date

May 2022

The Approach

Action & Learner-Centered

I used action mapping to understand the problem and create solutions. The client had previously experienced little business impact using traditional approaches and was keen to try something new. Within this framework, a range of principles were applied to create a solution that aligned with business goals while simultaneously putting learner experience at the forefront:

Coherent & Minimal: Following the coherence principle and taking inspiration from the aesthetics of modern technology, non-essential elements were excluded from the design.

Evidence-Based: Mayer’s Principles of Multimedia Learning were referenced throughout. Cognitive Load Theory and scenario design principles were considered.

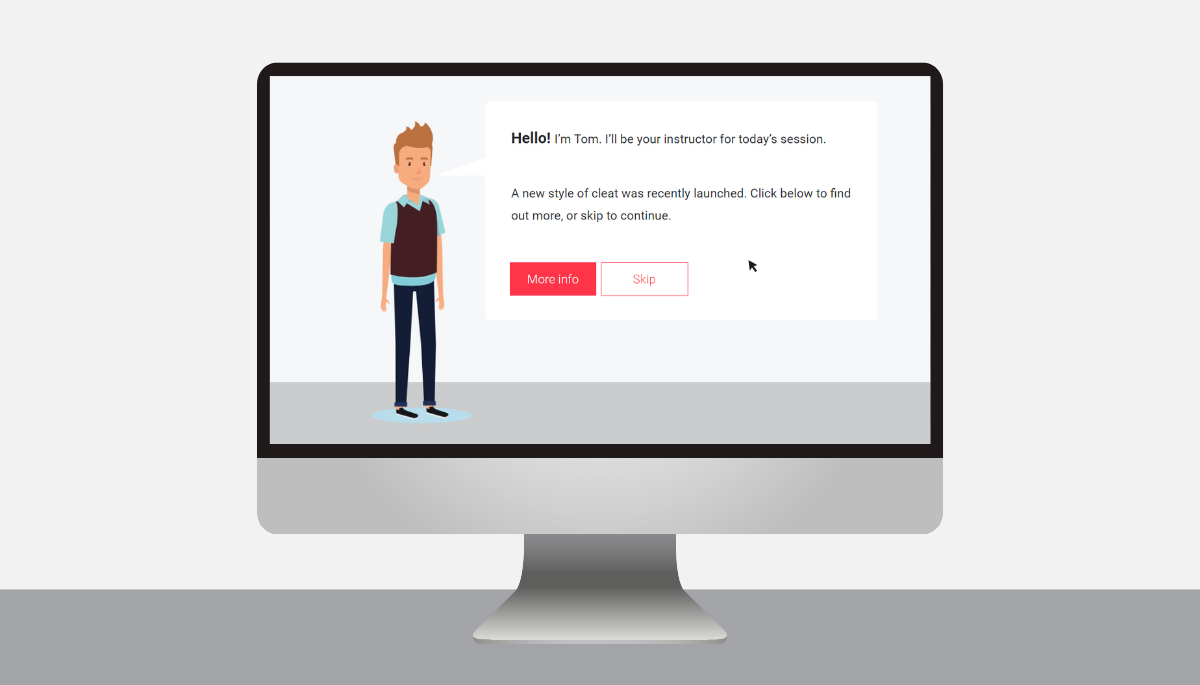

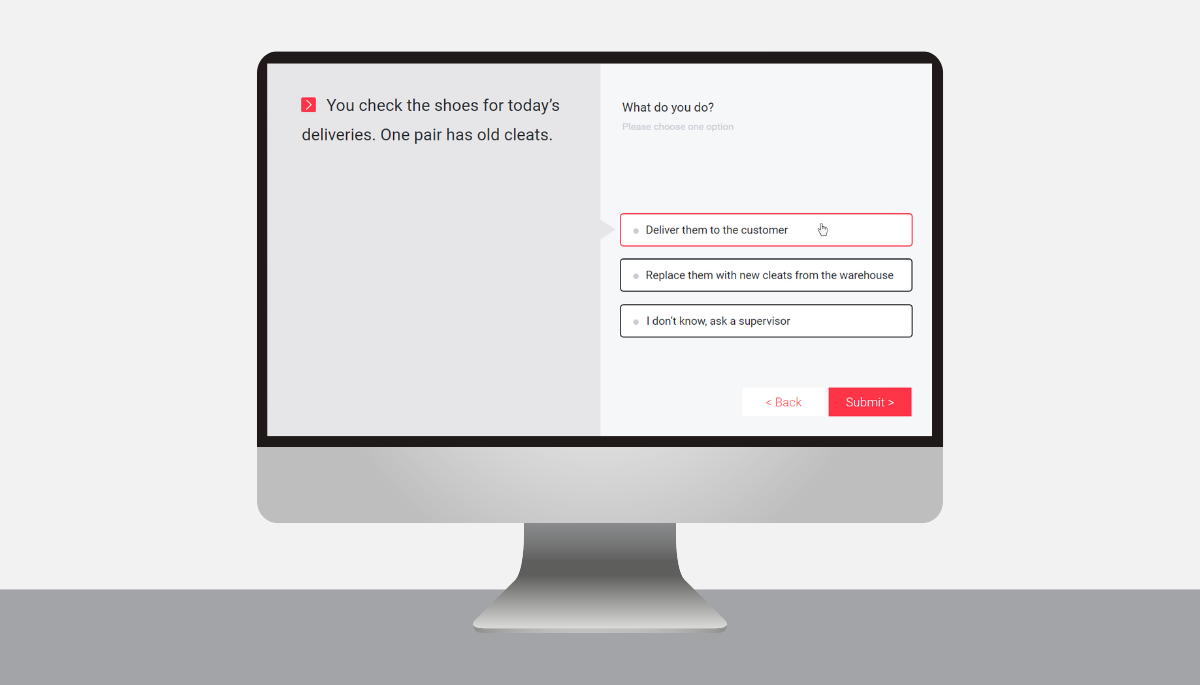

Learner-Centered: Learners had a wide range of on-the-job experience. In the activity everyone is given the opportunity to make real-life decisions; those who need extra support can pull additional information and/or ask a supervisor for help.

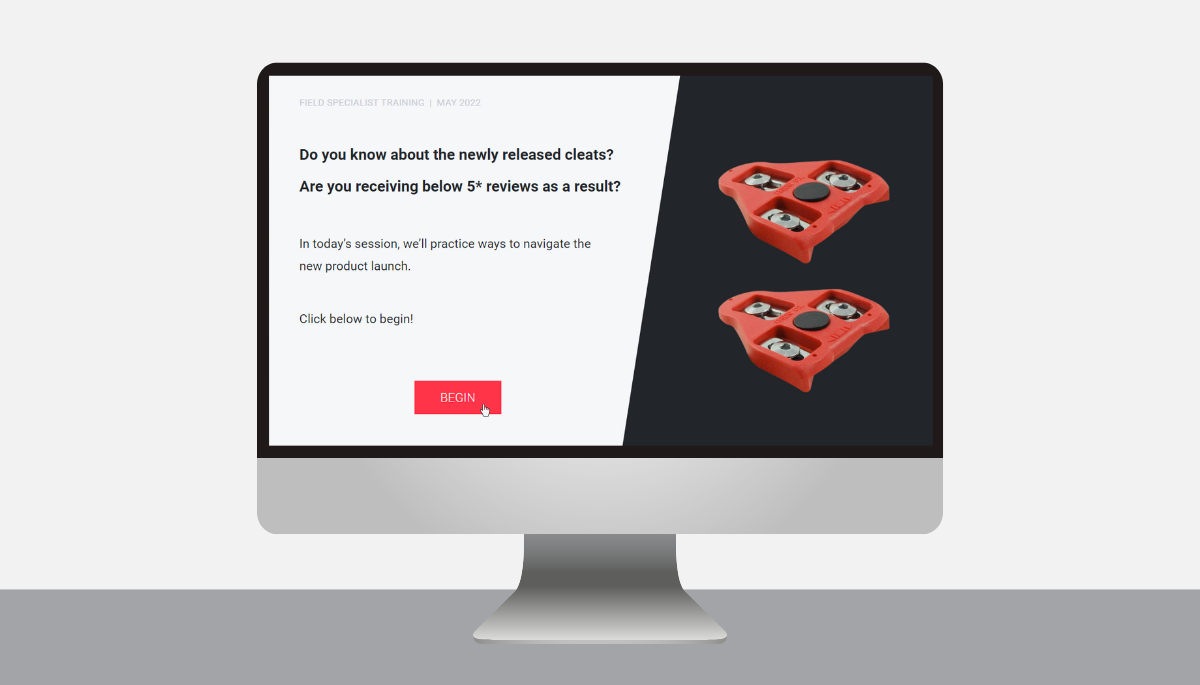

The Solution

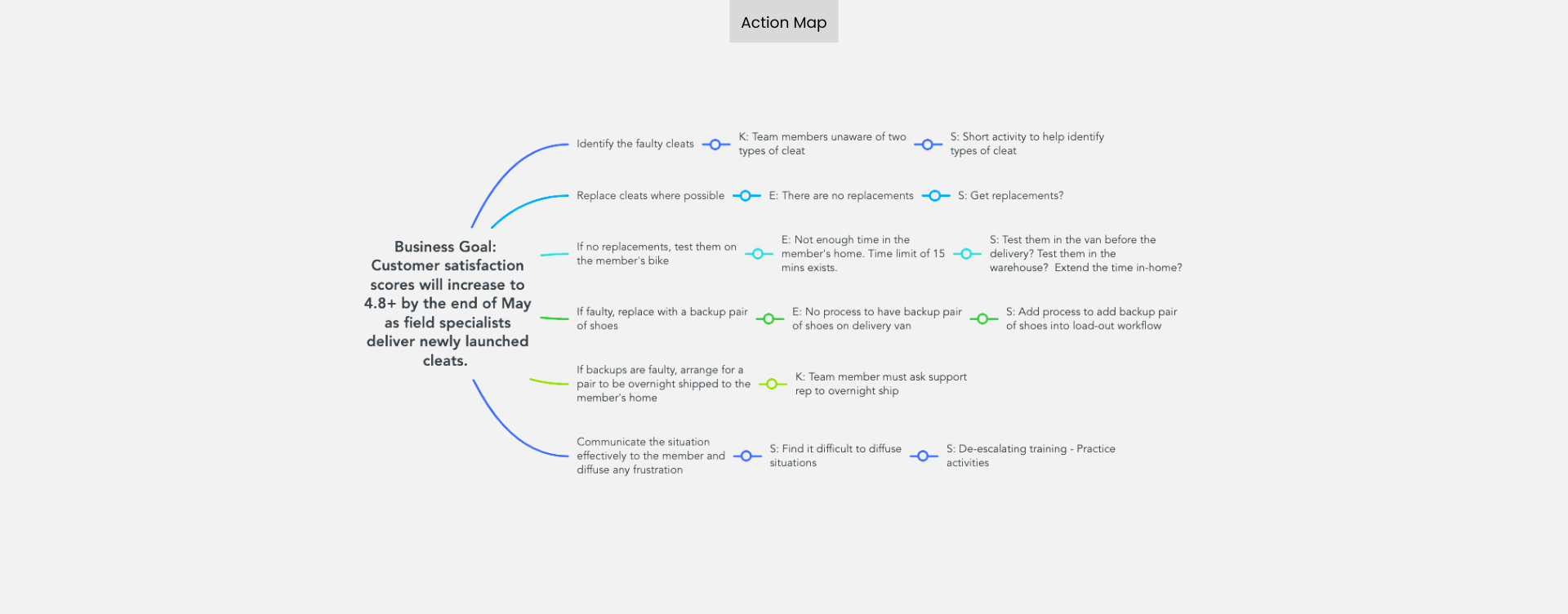

Branching Scenario Practice Activity

I designed a branching scenario for delivery team members, providing them with a safe space to make real-life decisions. The decision points are aligned with steps in the SOP and learners receive immediate feedback based on their choices. Learners have an opportunity to download a copy of the SOP at the end of the exercise for future use.